The Technical Support to Compete

American manufacturers need more than fast, reliable CNC machines. Success in today’s competitive global marketplace demands fast and reliable technical service and support as well. We call it Support ONE. At its heart is a new level of collaboration among American tool manufacturers, distributors and machine shop owners.

Milltronics Technical Service Specialists work seamlessly with our distributor partners to support both them and our customers with the “one-stop” support they need to compete. From installation and upgrades, to warranty and non-warranty service to troubleshooting and preventative maintenance Support ONE has got your back.

FAQ

What retention knobs should my machine use?

The standard retention knob used by Milltronics is the MAS 60 degree knob. Machines may be special ordered to use a different style. Details on the retention knob dimensions can be found here.

What are the power requirements for my machine?

The voltage requirement for a Milltronics machine is 208 to 240 volts AC three phase. KVA requirements vary by machine model. Specific details can be found in the instruction handbook for the machine model or from an authorized Milltronics representative in your area. Visit the Documentation Library to find the instruction handbook for your Milltronics machine.

Can current machine models use single phase power?

No, all current Milltronics machines require three phase power. Use of a phase converter is not recommended.

What kind of lubricants does the machine require?

Machine lubrication specifications can be found in the mechanical manual or Instruction Handbook (depending on age) for a specific machine model. Visit the Documentation Library to request the mechanical manual for your Milltronics machine.

The general way oil recommended is: Hangsterfer’s Way#2 way lube, Mobil Vactra 2, or an equivalent. The general grease specification is: Mobilgrease XHP 221, or equivalent.

Where can I find information on preventative maintenance for my machine?

The best source of information on preventative maintenance for your machine is the Instruction Handbook. Visit the Documentation Library to find the Instruction Handbook for your Milltronics machine.

What is the air requirement for a Milltronics machine?

Most Milltronics machine requires an air supply of at least 90 psi at 20 cubic feet per minute. Many ML lathes without a spindle gearbox, live tooling turret or collet closer do not have any requirement for air. Contact the Milltronics representative in your area for the requirements of a specific machine.

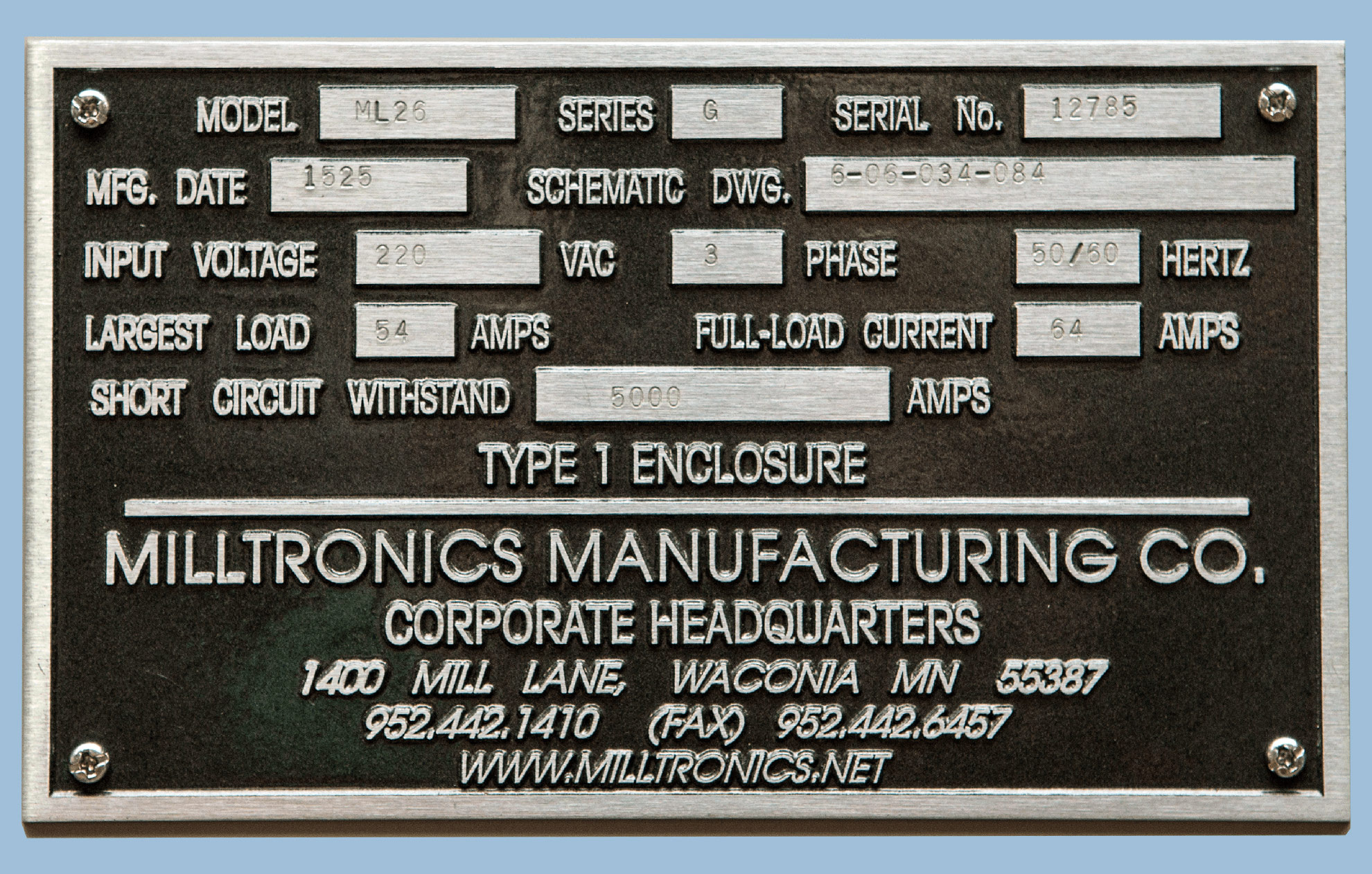

Where can I find my serial number and model information?

Please refer to the serial number plate typically located on the electrical cabinet door. This plate contains your model, series, serial number, manufacture date, voltage and amp requirements and more.

How are the date codes from the serial plate interpreted?

The date code on the serial number plate shows the year and the week in that year that the machine was built. A three digit date code is typically found on machines built in the 1990’s while a four digit date code represents machines built after December 31st, 1999.

Example: Date code ‘643’ means the machine was built the 43rd week (late October) of 1996. Date code ‘0315’ means the machine was built the 15th week (mid-April) of 2003.